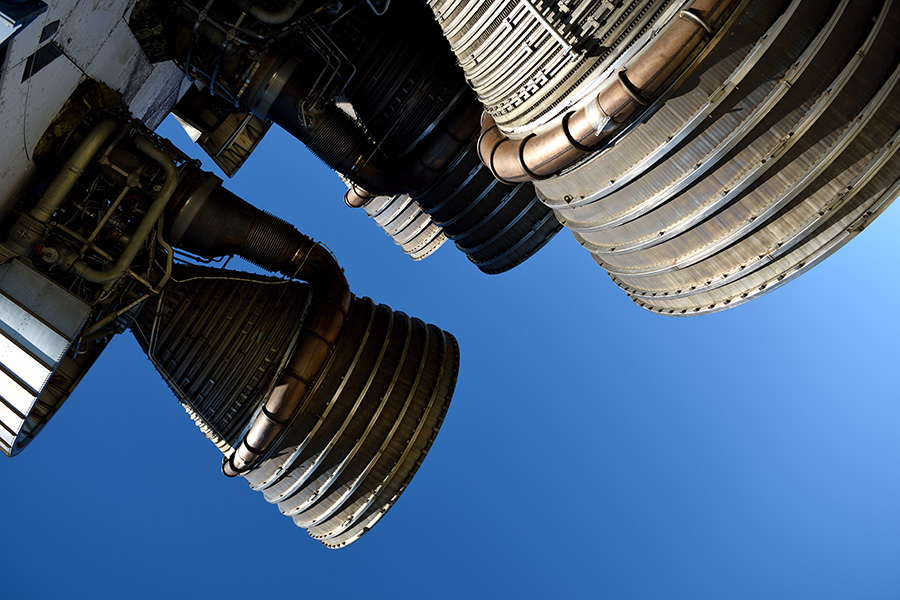

Aerospace

Run faster simulations, reduce print defects, and design lighter, stronger parts—without sacrificing interpretability or physics fidelity.

Aerospace systems operate under extreme conditions, with demanding requirements for strength, weight, and reliability. Designing and validating advanced materials, structures, and thermal systems is slow, data-intensive, and computationally expensive. The MIND Platform helps aerospace R&D and engineering teams accelerate this process—by training AI models on simulation and experimental data to optimize materials, reduce iteration cycles, and speed time-to-deployment without compromising physics fidelity.

Novel Material Identification

Accelerate discovery and validation of lightweight, high-strength, and temperature-resistant materials with data-driven materials modeling.

- Screen thousands of formulations using AI-assisted structure-property prediction

- Prioritize candidates based on performance under mission-specific load and thermal conditions

- Combine experimental and simulation data to learn faster and test less

Structural and Topology Optimization

Use AI to augment finite element workflows and optimize weight, stiffness, and failure resilience for flight-critical components.

- Run design iterations faster with AI-guided optimization loops

- Learn from past part performance to identify risky geometries or stress paths

- Support shape tuning for wings, fuselages, brackets, and other key structures

Multiphysics Simulation Acceleration

Reduce time-to-insight by training surrogate models on high-fidelity CFD, thermal, and structural datasets.

- Predict temperature, pressure, or stress distributions across operating regimes

- Enable faster trade studies with high-dimensional input spaces

- Preserve physics fidelity while reducing computational load

Additive Manufacturing Optimization

Improve build quality and part consistency in 3D printing workflows through AI-enhanced process monitoring and control.

- Predict defect likelihood based on geometry, scan strategy, and material parameters

- Analyze sensor data to detect anomalies in real time

- Tune print strategies to reduce warping, porosity, and rework

Solving Hard Problems Starts Here.

Let’s solve yours next. From simulation bottlenecks to multiscale manufacturing complexity—tell us what you’re up against. We’ll dig in together.