The Case Study

Multiscale Topology Optimization for Rear Floor Gigacast

Side Pole Impact Study demonstrating advanced optimization techniques for automotive structural design using periodic lattice structures and Bayesian optimization.

Project Overview

This study focuses on optimizing the Rear Floor Gigacast structure to achieve maximum weight reduction while maintaining critical safety performance under side pole impact conditions.

An auto manufacturer partnered with Multiscale to tackle a critical challenge in vehicle design: reducing the weight of the rear floor gigacast structure while ensuring it meets strict crash safety standards – specifically for side pole impact scenarios. Traditional methods of structural optimization often require

extensive simulation cycles and still fall short of identifying truly optimal, manufacturable solutions.

To solve this, Multiscale deployed its advanced topology optimization framework powered by Bayesian AI. The approach began by generating a vast design space using periodic lattice structures – such as BCC, BCC-Z, and Octet unit cells – within the original gigacast envelope. These complex geometries formed the basis for iterative structural refinement.

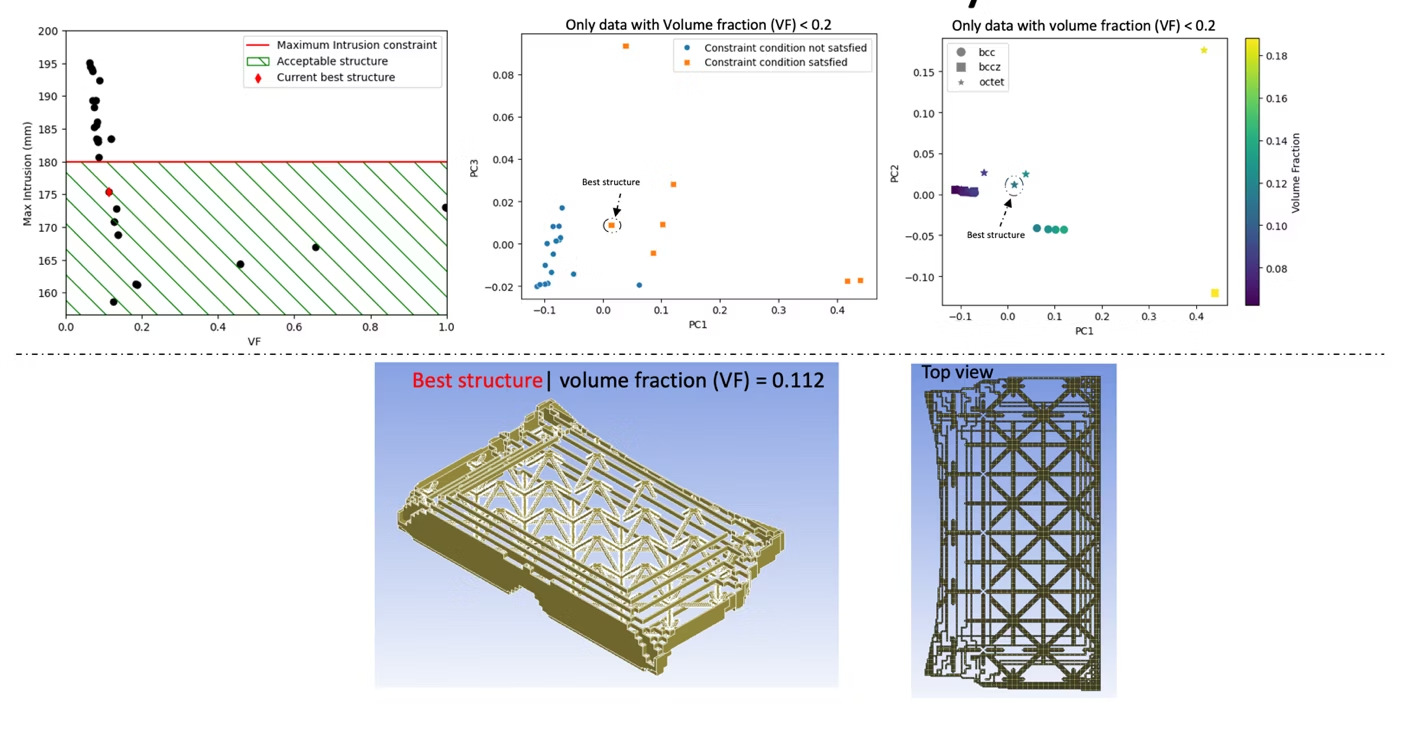

A Bayesian optimization loop guided the search through this high-dimensional design space, intelligently prioritizing simulations in regions with the greatest potential. By integrating directly with LS-DYNA crash simulations, the platform evaluated how each design performed against safety constraints, particularly the maximum allowable intrusion of 180 mm.

In just 30 iterations, Multiscale identified a design that reduced the component9s mass to approximately 11% of its original solid reference4while still passing the side pole impact requirement. This breakthrough showcases how engineering-grade AI can dramatically accelerate vehicle innovation, reduce material use, and improve safety4all at once.

Design Challenge

The automotive industry faces increasing pressure to reduce vehicle weight while maintaining or improving crash safety performance. Traditional solid structures often result in overengineered components that add unnecessary mass.

This drive for lighter vehicles is propelled by stringent fuel economy standards, emission reduction targets, and the demand for enhanced vehicle performance. However,

achieving these goals cannot compromise the paramount requirement of occupant safety, particularly under severe impact conditions and evolving regulatory landscapes.

Side pole impact represents one of the most challenging crash scenarios, requiring careful balance between structural integrity and weight optimization.

Unlike frontal or rear impacts which distribute forces over a wider area, a side pole impact concentrates a massive amount of energy into a very small, localized region of the vehicle. This leads to severe, localized deformation and poses a significant threat to occupant space. Consequently, designing components to effectively absorb and dissipate this energy without excessive intrusion is exceptionally complex, demanding highly efficient material distribution and advanced structural configurations.

Conventional design and optimization approaches often rely on iterative modifications and extensive physical prototyping, which are time-consuming and costly. These methods

frequently lead to designs that are either excessively heavy to meet safety standards or fail to achieve optimal material utilization, resulting in significant material waste and suboptimal performance-to-weight ratios. The need for innovative design methodologies capable of addressing these multi-faceted challenges is more critical than ever.

Optimization Objectives & Constraints

Primary Objective: Mass Minimization

The foremost objective of this optimization study is to minimize the total mass of the Rear Floor Gigacast. This is precisely managed by optimizing its volume fraction (VF), which represents the proportion of solid material within the defined design space.

Achieving significant mass reduction in automotive components directly translates to several key benefits:

- Improved Fuel Efficiency / Extended EV Range: Lighter vehicles consume less energy.

- Reduced Emissions: Lower fuel consumption contributes to a smaller carbon footprint.

- Enhanced Vehicle Dynamics: A lighter chassis can lead to better handling and acceleration.

- Material Cost Savings: Less material directly reduces production costs.

By employing a volume fraction optimization approach, we gain precise control over material distribution, enabling the identification of highly efficient, non-intuitive structural layouts that would be challenging to achieve through conventional

design methods.

Critical Constraint: Side Pole Impact Intrusion

A non-negotiable safety constraint is to ensure the maximum intrusion into the passenger compartment remains f 180 mm during a side pole impact event. This specific threshold is a critical benchmark, often mandated by stringent regulatory standards (such as FMVSS 214 in the US) and informed by biomechanical injury criteria.

Side pole impacts are particularly challenging crash scenarios due to the concentrated nature of the force applied to a relatively small area of the

vehicle. Exceeding the 180 mm intrusion limit could lead to severe injuries or fatalities for occupants, making this a paramount safety consideration.

The optimization process meticulously evaluates each design iteration against this constraint using advanced crash simulations. Designs failing to meet this criterion are penalized, guiding the optimization algorithm towards solutions that provide robust passenger protection without compromising on mass targets.

Design Space Generation Strategy

The initial and most critical step in this advanced multiscale topology optimization process involves defining a vast and intelligent design space. This is achieved by systematically integrating periodic lattice structures, which are key to unlocking significant weight reduction potential while ensuring structural integrity. This methodical approach ensures that the subsequent optimization algorithms have a rich array of possibilities to explore, leading to truly innovative and high-performing designs.

Lattice Structure Selection

Design Space Expansion

This strategic tiling and variation in unit cell types allows for the creation of thousands of unique structural configurations. By parameterizing properties such as strut thickness, cell size, and orientation, we generate a high-dimensional design space. This extensive exploration capability is crucial for topology optimization, enabling the Bayesian AI to identify non-intuitive, highly efficient designs that traditional methods might overlook. It ensures a comprehensive search for the optimal solution, avoiding local minima and pushing the boundaries of what’s possible in lightweighting.

This comprehensive generation of design alternatives is foundational to Multiscale’s AI-driven optimization framework. It provides the necessary breadth and depth for the Bayesian optimization loop to efficiently navigate and discover designs that meet stringent performance criteria, such as crash safety, while drastically reducing material usage.

Lattice Unit Cell Types

BCC (Body-Centered Cubic)

The BCC unit cell provides an excellent strength-to-weight ratio and good isotropic properties, making it highly efficient for minimizing mass while maintaining structural integrity. Its distinctive diagonal struts, connecting cube corners to center points, allow for effective load distribution in multiple directions. This makes BCC a fundamental choice for lightweighting applications where multidirectional forces are present, offering a balanced performance profile.

BCC-Z (Modified BCC)

This is an enhanced BCC structure that incorporates additional vertical reinforcement along the Z-axis. This modification significantly improves directional strength and stiffness, particularly important for resisting forces aligned with the Z-axis, such as those experienced during a side pole impact. The BCC-Z unit cell is ideal for areas requiring heightened resistance to specific loading conditions, providing tailored reinforcement where needed.

Octet

The Octet unit cell combines both tetrahedral and octahedral elements in its intricate geometry, resulting in superior stiffness and exceptional energy absorption characteristics. Its highly interconnected structure allows for efficient distribution of stress and strain, making it particularly effective in scenarios requiring high impact resistance and energy dissipation. The Octet lattice is crucial for enhancing safety performance in crashcritical zones.

The strategic combination of these lattice types within the design space enables a comprehensive exploration of structural possibilities. This multi-architecture approach allows the optimization algorithm to select the most appropriate unit cell for each region of the gigacast, leveraging their unique advantages to achieve optimal performance under diverse loading conditions, ultimately leading to significant weight reduction without compromising safety.

Optimization Workflow

A sophisticated Bayesian optimization approach was implemented to efficiently explore the vast design space and identify optimal structural configurations. This iterative process is crucial for navigating the complex interplay between material properties, geometric design, and performance criteria, ensuring that the final solution is not only lightweight but also robust and safe.

Bayesian Optimization Loop

This intelligent loop serves as the brain of the optimization process. It systematically explores the vast structural design space, leveraging a probabilistic model to predict the performance of unsimulated designs. By intelligently selecting the most promising candidate designs for evaluation, it significantly reduces the number of expensive high-fidelity simulations required, accelerating the discovery of

optimal and non-intuitive solutions. This approach balances exploration of new

design territories with exploitation of known highperforming regions, ensuring

efficient convergence to the best possible outcomes.

LS-dyna Simulations

For each selected design, highfidelity crash simulations are performed using LS-DYNA, an advanced explicit finite element analysis software. These simulations meticulously replicate realworld crash scenarios, such as side pole impacts, to precisely assess the structural performance against stringent safety requirements. Key metrics evaluated include intrusion levels, energy absorption capabilities, and stress distribution, providing critical data points for the optimization algorithm. Despite their computational intensity, these simulations are indispensable for validating the structural integrity and crashworthiness of the proposed designs.

Design Assessment

Following each simulation, the performance of the evaluated design is rigorously assessed against the predefined crash targets and overall optimization objectives,

including mass reduction, stiffness, and safety standards like FMVSS 214. This

assessment quantifies how well the design performs, identifies any constraint

violations, and calculates a fitness score. This performance feedback is then

fed back into the Bayesian optimization loop, allowing the model to refine its

understanding of the design space and guide subsequent iterations towards even better performing and more efficient structural configurations.

This continuous feedback mechanism between design exploration, simulation, and assessment allows for the rapid identification and refinement of designs that achieve superior performance under complex loading conditions. Ultimately leading to breakthroughs in lightweighting and structural efficiency for components like the rear floor gigacast.

Breakthrough Results

The application of the advanced Multiscale topology optimization process yielded truly remarkable outcomes, significantly pushing the boundaries of what’s possible in lightweight automotive component design. These breakthrough results underscore the effectiveness of our sophisticated approach in achieving substantial weight reduction without compromising the stringent safety and performance requirements critical for modern vehicle structures.

By intelligently integrating diverse lattice structures and leveraging a robust Bayesian optimization workflow, we were able to efficiently navigate an incredibly complex design space. The following key metrics highlight the profound impact of this optimization on the rear floor gigacast:

30

Iterations

Optimization convergence was decisively achieved after approximately 30 iterations. This rapid convergence demonstrates the high efficiency of the Bayesian optimization algorithm in quickly identifying optimal design candidates, significantly reducing computational time and resources typically required for such complex engineering challenges.

0.112

Volume Fraction

The final optimized design proudly achieves a mere 11.2% of its original solid mass. This exceptionally low volume fraction signifies an almost complete reimagining of the component’s internal structure, utilizing material only where absolutely necessary to bear loads and meet performance criteria.

89%

Mass Reduction

This translates to an approximate 89% weight savings when compared to the initial solid reference design. Such a dramatic reduction in mass directly contributes to enhanced vehicle efficiency, improved handling, and reduced material consumption, aligning perfectly with modern automotive industry goals for sustainable and high performing vehicles.

These figures represent not just an incremental improvement, but a paradigm shift in the design and manufacturing of large structural components like the rear floor gigacast. The ability to achieve such significant mass reduction while rigorously adhering to all predefined safety standards, including critical crashworthiness, validates the potential of multiscale topology optimization as a transformative technology in automotive engineering. The results pave the way for future innovations in vehicle lightweighting and overall structural integrity.

Final Optimized Design

The final optimized design represents a remarkable achievement, successfully meeting stringent crash targets while boasting an incredibly low volume fraction of approximately 0.112 VF. This means the component utilizes only about 11% of the material compared to its initial solid reference mass. Such a significant reduction is a testament to the precision of the Multiscale topology optimization process, ensuring that material is placed only where it contributes most effectively to structural integrity and loadbearing capacity. Furthermore, the optimization yielded multiple alternative structural configurations that also satisfy all design requirements. This invaluable flexibility provides manufacturers with options to consider various production methodologies, material availability, and cost implications, making the solution highly adaptable for real-world application.

While further minor reductions in volume fraction were technically achievable, the current optimized design already significantly exceeded the customer’s initial requirements and expectations. This early overperformance highlights the robustness and efficiency of our methodology, indicating a substantial competitive advantage for the client in terms of material savings, weight reduction, and enhanced performance.

This breakthrough unequivocally demonstrates the immense potential for achieving significant weight reduction in large automotive structures like the rear floor gigacast without compromising critical safety performance metrics. The methodologies employed pave the way for a new paradigm in vehicle lightweighting, contributing to improved fuel efficiency, extended range for electric vehicles, and a reduced environmental footprint, all while maintaining or even enhancing occupant safety standards.